Lidar, as an advanced sensing technology, plays a crucial role in various fields such as autonomous driving, robotics, drones, and industrial automation. PCBs for Lidar systems, as the core components, directly influence the performance and reliability of the entire system. This article will explore the development history, key technologies, and applications of PCBs for Lidar in different domains.

Development History of PCBs for Lidar

The development of PCBs for Lidar has gone through several important stages. In the early days, traditional rigid board designs were used for Lidar PCBs, mainly in research laboratories and military applications. With the rise of autonomous driving and robotics, Lidar PCBs have gradually evolved towards miniaturization, high integration, and cost reduction. Rigid boards have been replaced by flexible circuit boards and rigid-flex boards, providing better mechanical adaptability and reliability. In recent years, with advancements in new materials and manufacturing processes, Lidar PCBs are moving towards higher performance, higher density, and smaller sizes.

Key Technologies of PCBs for Lidar

High-Frequency Signal Transmission Technology: Lidar PCBs require handling high-frequency signals, necessitating considerations of signal integrity and transmission stability during the PCB design and manufacturing processes. Employing suitable layer stack-up methods, impedance control, and signal layer routing rules can reduce signal distortion and interference, thereby improving system performance.

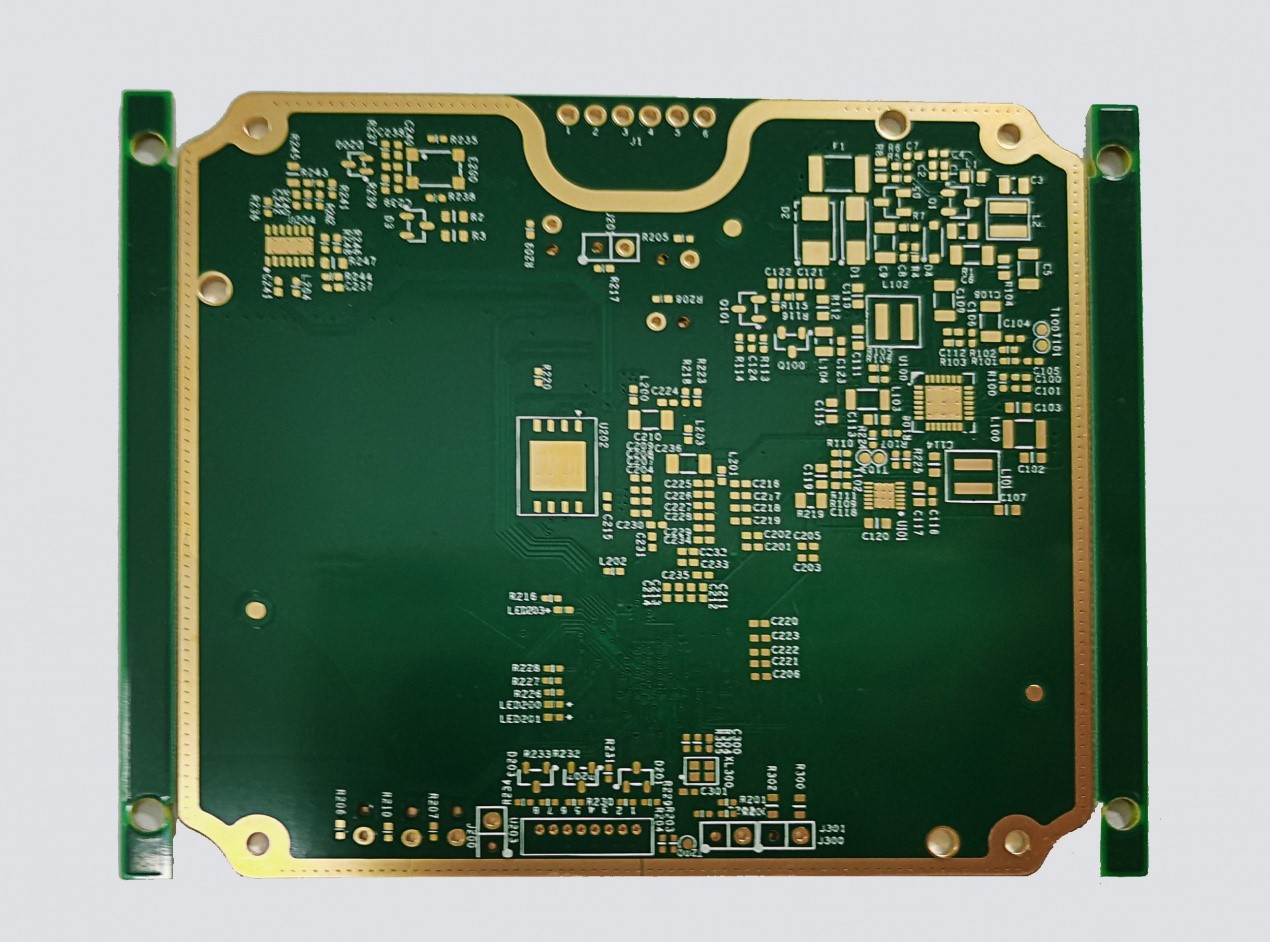

High-Density Layout and Packaging Technology: To achieve higher integration and smaller sizes, Lidar PCBs need to adopt high-density layout and packaging technologies. This includes using fine traces and spacing for circuit board fabrication, employing multilayer board designs, and utilizing advanced packaging techniques such as BGA packaging to achieve more compact designs and higher signal transmission rates.

Thermal Management Technology: Lidar systems generate a significant amount of heat during operation, making thermal management crucial for maintaining system performance and reliability. Lidar PCBs require proper heat dissipation design, including heat sinks, thermal pads, and heat dissipation holes, to ensure stable operation of Lidar in high-temperature environments over extended periods.

Applications of PCBs for Lidar Autonomous Driving

Lidar PCBs are critical sensing components in autonomous driving systems. By providing highly accurate 3D point cloud data, they enable precise perception of the surrounding environment and obstacle detection, thus offering autonomous vehicles accurate environmental awareness capabilities.

Robotics: Lidar PCBs play a vital role in robot navigation and environmental perception. By obtaining precise structural information about the environment, robots can achieve high-precision positioning, map construction, and path planning, enabling intelligent navigation and task execution.

Drones: Lidar PCBs can be used for obstacle avoidance and precise positioning in drones. By acquiring 3D information about the surrounding environment, drones can perceive obstacles in real time and intelligently navigate around them, thereby enhancing flight safety and operational flexibility.

Industrial Automation: Lidar PCBs can be applied to object detection and ranging in industrial automation. By obtaining information about the position and shape of objects, industrial robots can achieve accurate object grasping and positioning, thereby improving production efficiency and quality.

Conclusion: With the continuous development and widespread adoption of Lidar technology, PCBs for Lidar play a vital role in driving automation and intelligence. By continuously enhancing the design and manufacturing technologies of Lidar PCBs, it is possible to realize Lidar systems with higher performance, smaller sizes, and higher integration, thereby promoting development and innovation in related fields.