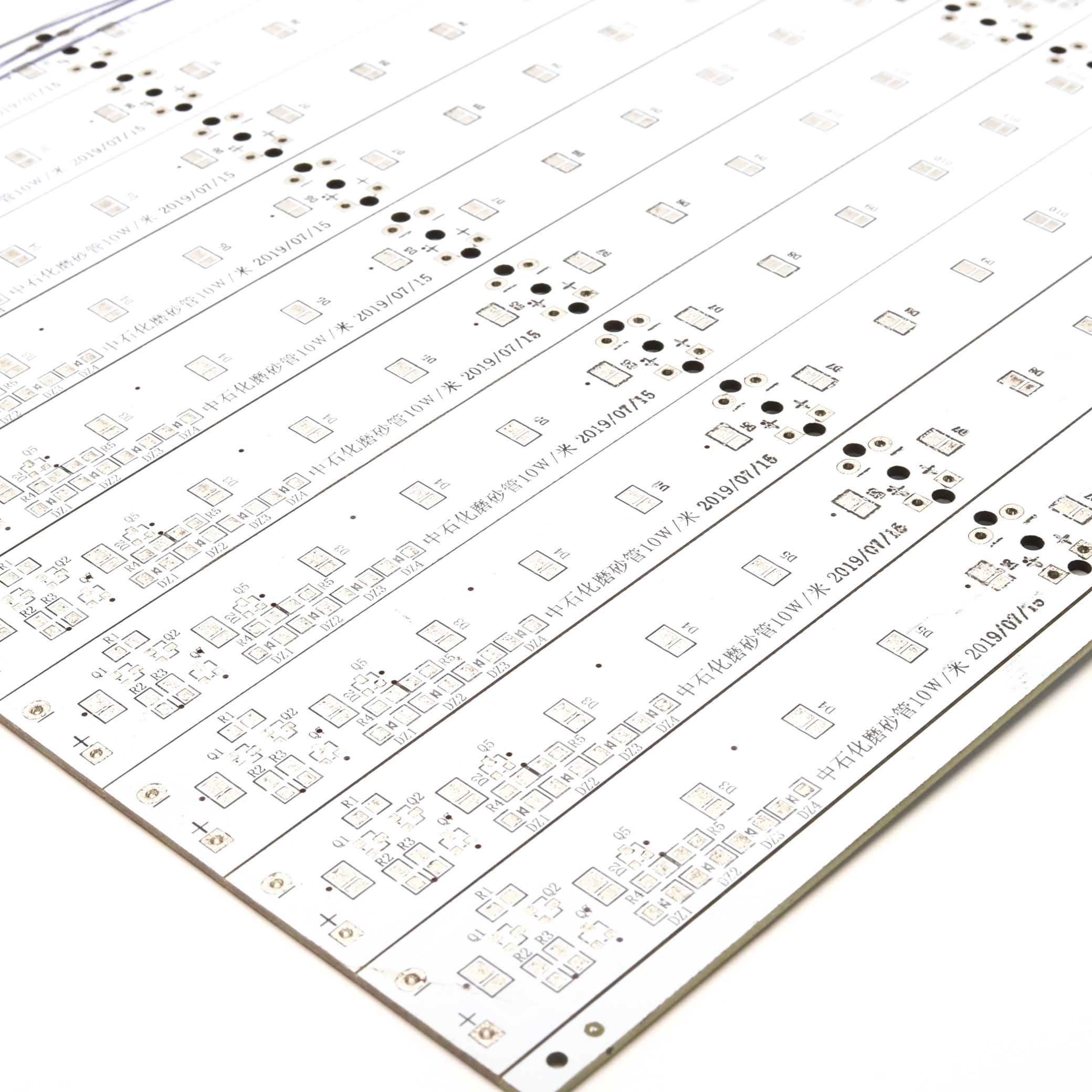

With the rapid development and continuous innovation of LED technology, LED PCB plays a crucial role in the lighting industry. LED PCB not only provides support and circuit connections for LED lighting systems but also enhances LED performance and lifespan through excellent heat dissipation. Among them, aluminum substrate, as a commonly used material in LED PCB, possesses outstanding heat dissipation and electrical properties, making it the preferred choice in the lighting industry. This article will delve into the common applications of LED PCB in the lighting industry and elucidate the significance of aluminum substrate in LED PCB.

Common Applications of LED PCB in the Lighting Industry:

- Indoor Lighting

LED PCB can be embedded in ceilings, walls, or floors to illuminate entire rooms. By controlling the circuitry and arrangement of LED chips, different colors and brightness levels can be achieved to meet various residential lighting needs.

- Commercial Lighting

LED PCB is extensively used as the primary light source in commercial venues such as shopping malls, hotels, and office buildings. It can be manufactured in various shapes and sizes, such as light strips or panels, to accommodate diverse architectural structures and decorative requirements. LED PCB offers dimmable and color temperature-adjustable features, allowing adjustments to create comfortable and cozy lighting environments for different scenarios.

- Automotive Lighting

LED PCB finds applications in automotive front lights, tail lights, brake lights, and more. Compared to traditional bulbs, LED PCB offers higher brightness and lower power consumption. It also enables various lighting effects, such as welcome lights and daytime running lights. Additionally, LED PCB can be utilized for interior lighting, providing passengers with a comfortable ambient illumination.

- Outdoor Lighting

LED PCB is suitable for road lighting, billboard illumination, landscape lighting, and other outdoor applications. With its durability, waterproofing capabilities, and high-temperature resistance, LED PCB can function reliably in harsh outdoor environments. Compared to traditional lighting devices, LED PCB delivers higher brightness and lower energy consumption. Moreover, it allows for remote control and intelligent management.

The Importance of Aluminum Substrate in LED PCB

1.Excellent Heat Dissipation

Effective thermal management is crucial in LED lighting applications, and aluminum substrate stands out as an ideal choice due to its superior heat dissipation properties. LED chips generate a considerable amount of heat during operation, and inadequate heat dissipation can lead to reduced LED lifespan and performance degradation. Aluminum substrate exhibits excellent thermal conductivity, swiftly transferring heat generated by LED chips to the surrounding environment, thereby reducing LED operating temperatures and enhancing longevity and stability.

2.Good Electrical Properties

Aluminum substrate possesses favorable electrical characteristics, making it suitable for LED PCB design and manufacturing. Firstly, aluminum substrate has low electrical resistance, which reduces energy loss during current transmission, thereby improving LED efficiency. Secondly, aluminum substrate exhibits excellent thermal conductivity and mechanical strength, ensuring circuit stability and reliability. Additionally, aluminum substrate offers excellent electromagnetic shielding capability, effectively reducing interference and electromagnetic leakage, thus enhancing LED system’s anti-interference capabilities.

3.Cost-Effectiveness

Compared to other materials, aluminum substrate provides cost advantages in LED PCB manufacturing. Aluminum substrate has relatively low production costs, and the processing and assembly procedures are relatively straightforward, resulting in cost savings and shorter manufacturing cycles. Furthermore, the excellent heat dissipation performance of aluminum substrate reduces the thermal management requirements for LED systems, minimizing the need for heat sinks and other cooling devices, leading to further cost savings.

4.Flexible Design and Application

Aluminum substrate offers flexible design and application characteristics, catering to various LED lighting scenarios. It can be custom-designed based on LED chip layouts and power requirements to meet different lighting demands. Additionally, aluminum substrate can be combined with other materials such as ceramic substrates or polymer substrates to achieve more diversified LED PCB designs.

The utilization of aluminum substrate in LED PCB is driven by its outstanding heat dissipation performance, good electrical properties, cost-effectiveness, and flexibility in design and application. By selecting aluminum substrate as the material for LED PCB, LED system performance and reliability can be effectively enhanced, meeting the requirements of diverse lighting applications. With the continuous development of LED technology and the expansion of the LED lighting market, the prospects of aluminum substrate in LED PCB applications will continue to expand.