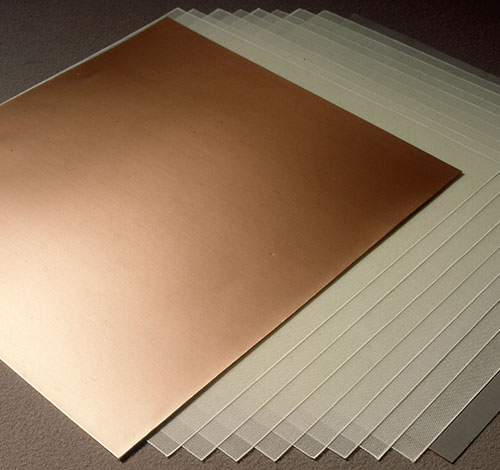

With the growing global awareness of environmental protection, industries from all sectors are actively seeking environmentally friendly solutions to replace traditional products and materials. In the electronics industry, PCB plays a crucial role as a fundamental component, and its manufacturing materials are continuously being improved to meet the demands of sustainability. Among them, halogen-free PCB, as an environmentally friendly and high-performance option, is increasingly becoming the focus of the industry. This article will explore the characteristics, advantages, application prospects, and positive environmental impact of halogen-free PCB. (Figure: Halogen-free Tg150 high-rigidity copper-clad laminate)

Characteristics and Advantages of PCB

Halogen-free Board Halogen-free PCB is a type of PCB manufactured using halogen-free materials, which differ from traditional materials containing halogen compounds. It possesses the following characteristics and advantages:

1.Environmentally friendly material: Halogen-free PCB uses halogen-free materials, eliminating elements such as chlorine and bromine. Halogen compounds are considered potential threats to the environment and human health, as they may release toxic gases during combustion or processing. The use of halogen-free PCB reduces potential harm to the environment and human health.

2.High-temperature performance: Halogen-free PCB exhibits excellent high-temperature performance, maintaining stable electrical properties and mechanical strength in high-temperature environments. This makes it widely applied in industries such as automotive electronics and aerospace, which require operation under high-temperature conditions.

3.Flame-retardant properties: Halogen-free PCB demonstrates excellent flame-retardant properties, effectively reducing the spread of fire in electronic products during accidents. This is because the halogen-free materials used in halogen-free PCB are less combustible, and the gas generated during combustion is limited, minimizing the release of toxic gases.

Application Prospects of Halogen-free PCB

With the increasing awareness of environmental protection, halogen-free PCB holds vast application prospects in the electronics industry. Here are some potential application areas for halogen-free PCB:

1.Communication equipment: Halogen-free PCB can be used in the manufacturing of mobile phones, routers, base stations, and other communication devices, providing users with safer and more reliable communication services.

2.Automotive electronics: In the automotive industry, halogen-free PCB can be employed in the manufacturing of control systems for electric vehicles, charging stations, in-vehicle entertainment systems, and more, contributing to the sustainable development of automobiles. (Figure: Halogen-free Automotive PCB)

3.Medical equipment: With its antimicrobial properties and high reliability, halogen-free PCB can be applied in the field of medical equipment, enhancing the safety and performance of medical devices.

In conclusion, halogen-free PCB, as a revolutionary change in environmentally friendly electronic manufacturing, offer advantages such as environmental friendliness, high-temperature performance, and flame-retardant properties. With the continuous improvement of environmental awareness, the application of halogen-free PCBs will become more widespread in the electronics industry. Moreover, we encourage all stakeholders in the electronic manufacturing industry to intensify research and development efforts, promote the application of more environmentally friendly technologies and materials, and together build a more sustainable future.