In the design and manufacturing of power supply products, the Printed Circuit Board (PCB) plays a crucial role. The selection of PCB dielectric is one of the key factors in ensuring the performance and reliability of power supply products. In this article, we will introduce the factors to consider when choosing PCB dielectric thickness and provide some suggestions to help you make informed decisions in designing and manufacturing power supply products.

A. Power Requirement: The power requirement of the power supply product is the primary factor to consider when selecting PCB dielectric thickness. Higher power supply products require thicker PCB dielectric to provide sufficient heat dissipation capability and current transmission capacity. Generally, as the power increases, the thickness of the PCB dielectric should also increase accordingly. Ensure that the chosen PCB dielectric can withstand the required power and maintain stable performance.

B. Thermal Management: Effective thermal management is crucial for the performance and lifespan of power supply products. Choosing the appropriate PCB dielectric thickness can help dissipate heat effectively and reduce heat accumulation. Thicker PCB dielectric typically has better heat dissipation capability, allowing for better dispersion and transmission of heat, thereby lowering the temperature of the circuit board. For high-power power supply products, selecting thicker PCB dielectric can provide better thermal management and reduce the risks of overheating.

C. Space Limitation: In power supply product design, there is often a need to accommodate as many components and circuits as possible within limited space. However, thicker PCB dielectric takes up more space. Therefore, when selecting PCB dielectric thickness, it is necessary to balance space requirements and performance demands. For space-constrained applications, considering thinner PCB dielectric may be an option, but it should still meet the requirements for power and thermal management. Taking into account both space and performance factors, choose the PCB dielectric thickness that best suits your design.

D. Electrical Performance: The thickness of PCB dielectric also affects the electrical performance of the circuit. Thicker PCB dielectric can provide lower resistance and better signal integrity. However, excessively thick PCB dielectric may lead to increased signal transmission delay. When choosing PCB dielectric thickness, it is essential to consider the signal speed and electrical performance requirements of the circuit. Ensure that the selected PCB dielectric thickness does not have adverse effects on signal transmission and circuit performance.

When selecting PCB dielectric thickness, it is also important to consider the recommendations and guidance from manufacturers. Different applications and manufacturing processes may have specific requirements and limitations. Collaborating and consulting with professional PCB manufacturers and engineers can provide more accurate advice and customized solutions.

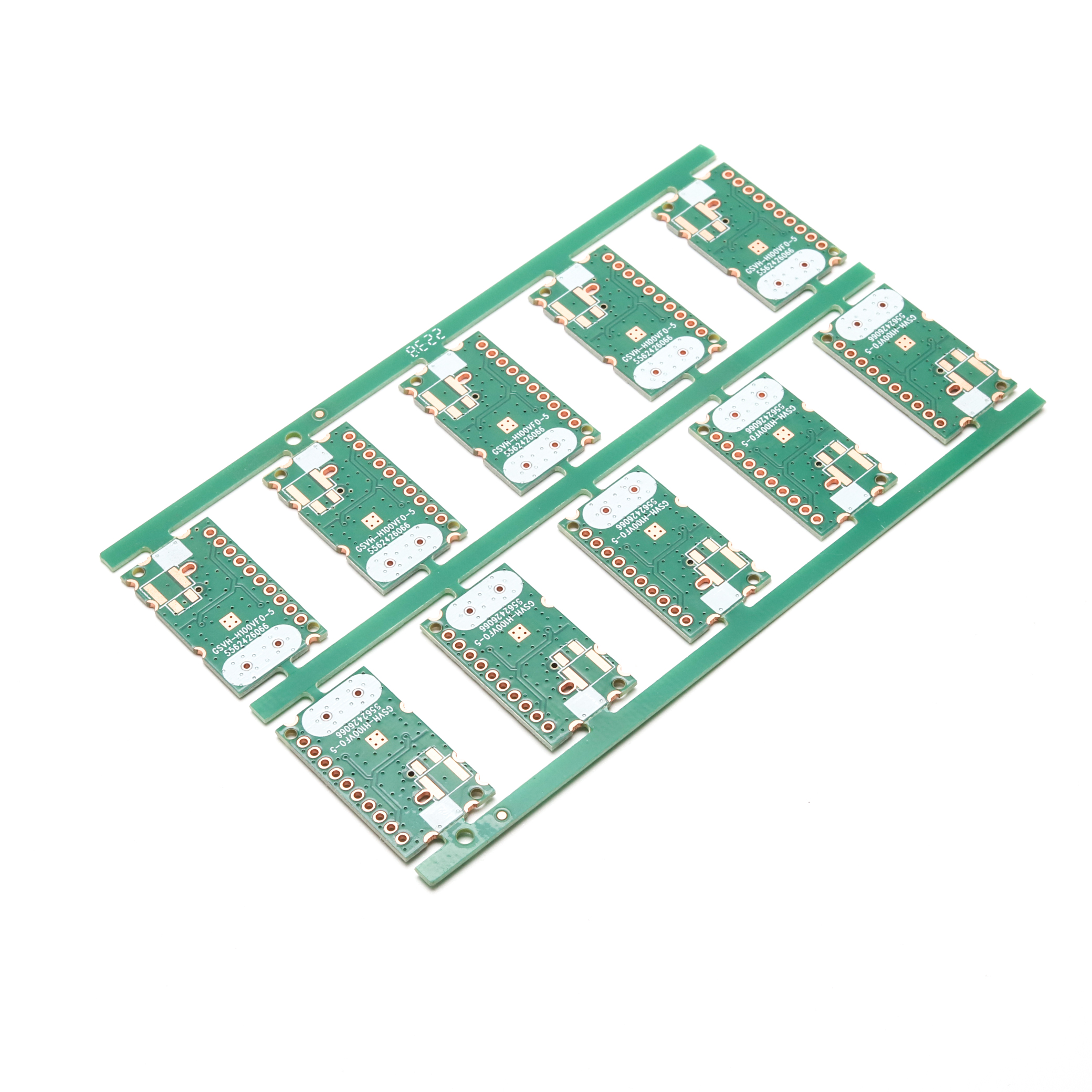

Choosing the appropriate PCB dielectric thickness is critical in the design and manufacturing of power supply products. Power requirements, thermal management, space limitations, and electrical performance are key factors influencing the selection. Based on specific application requirements, you can choose the suitable PCB dielectric thickness based on power size and balance between thermal management and space limitations. Additionally, consider the electrical performance requirements of the circuit to ensure that the chosen PCB dielectric thickness does not have adverse effects on signal transmission and circuit performance. By considering these factors comprehensively and collaborating with professional manufacturers, you will be able to select the optimal PCB dielectric thickness to ensure the performance and reliability of power supply products. For your power supply PCB needs, Y-West Electronics specializes in producing power supply PCBs. (Attached image: Thick Copper Power Supply PCB) If you have any inquiries, please feel free to contact us.