PCB inspection is an essential process in ensuring the quality of electronic products. By inspecting PCB boards, potential defects and issues can be detected and corrected early, ensuring the performance, reliability, and safety of the products. The selection and application of PCB inspection methods are crucial for quality control in the production process. In this article, we will provide a detailed analysis of several common PCB inspection methods.

Visual Inspection:

Visual inspection is one of the most fundamental and widely used PCB inspection methods. Operators use magnifying glasses or microscopes to carefully observe the PCB boards, examining the circuit connections, solder joints, and component placements to identify any defects, short circuits, poor soldering, or component misplacements.

AOI (Automated Optical Inspection):

AOI technology utilizes high-resolution cameras and image processing software to automatically inspect the lines, solder pads, and components on PCB boards. It can rapidly and accurately detect soldering defects, silk screen errors, component misalignments, and improve inspection efficiency.

Electrical Performance Testing:

Electrical performance testing methods include dedicated testers, universal testers, flying probe testers, non-contact electron beam testers, conductive cloth testers, capacitive testers, and brush testers. Among these, the most commonly used devices are dedicated testers, universal testers, and flying probe testers.

Dedicated Testing:

Dedicated testing is called so because the fixtures used are specific to a particular product. Different products’ PCBs cannot be tested using the same fixture, and these fixtures are not reusable.

Universal Testing:

The basic principle of universal testing is based on the concept of grid density, which refers to the distance between grids (sometimes represented by hole density). Universal testing utilizes this principle and performs electrical performance testing based on the position of holes, using an A-pin to pass through the mask. Therefore, the production of fixtures for universal testing is simple and fast, and the probes can be reused. Universal testing uses a large needle plate with a standardized grid and can produce active probe needle plates tailored to different products. During mass production, simply changing the active probe needle plate allows testing for different part numbers. Additionally, to ensure smooth operation of the PCB circuit system, a specific contact point needle plate is used for open/short electrical performance testing on the universal electrical performance testing host, which is known as an automated testing machine.

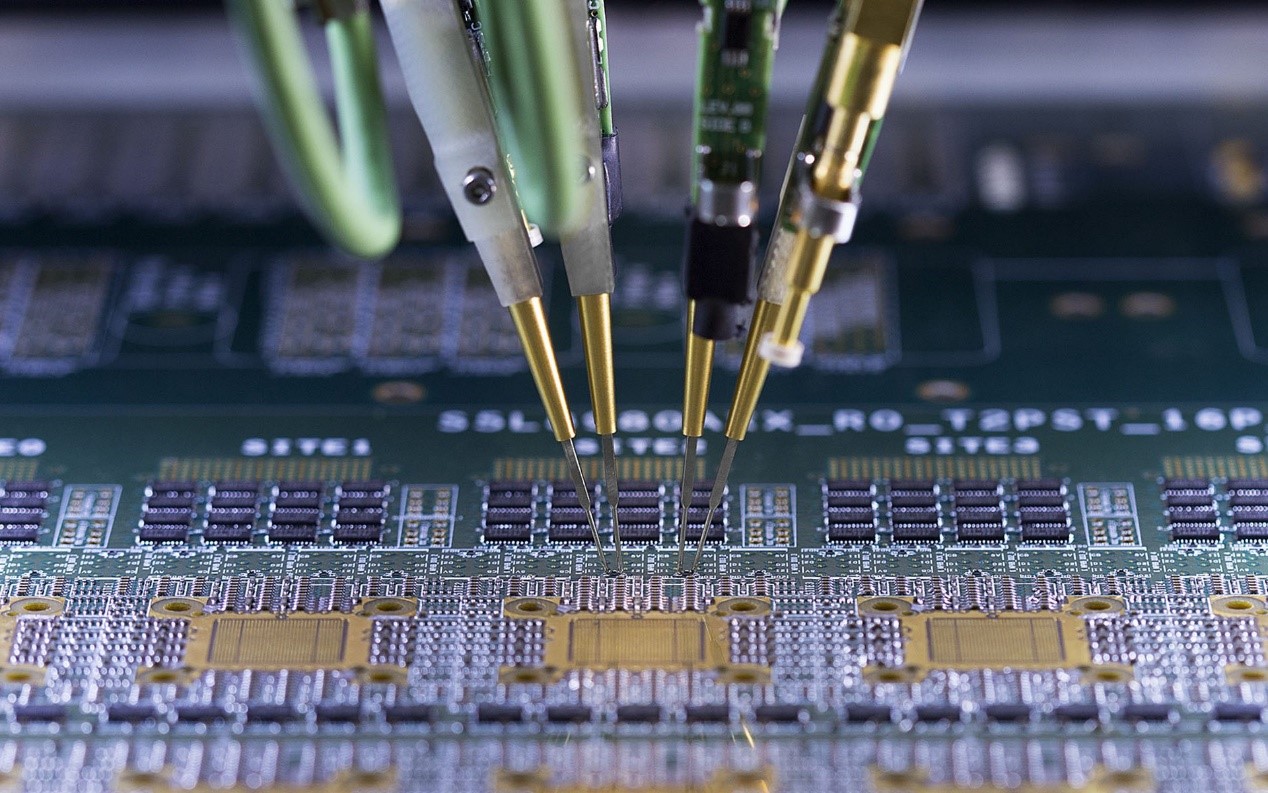

Flying Probe Testing:

Flying probe testing operates on a simple principle, requiring only two probes to move in the X, Y, and Z directions to individually test the two endpoints of each circuit. Therefore, there is no need to produce expensive fixtures. However, due to the endpoint testing nature, the testing speed is slow, approximately 10-40 points/s. As a result, flying probe testing is more suitable for sample testing and small-scale production. It can be applied to boards with extremely high density.

Dimensional Measurement:

For PCB dimensions such as outer shape, hole diameter, hole position, solder pads, etc., three-dimensional testers are generally used for measurement. Line width and spacing are typically measured using a line width tester. Microscopes may be used for inspecting minute dimensions. PCB warpage can be measured using a warpage inspection machine. Copper thickness is measured using a copper thickness tester, while board thickness is measured using a long-arm tester.

PCB inspection is a critical step in ensuring the quality of electronic products. By selecting and applying appropriate inspection methods, the quality control of the production process can be enhanced, ensuring the reliability and stability of electronic products to meet market and customer requirements. Longyu PCB undergoes high-quality inspections before shipment to meet customer demands. If you have any inquiries, please feel free to contact us.